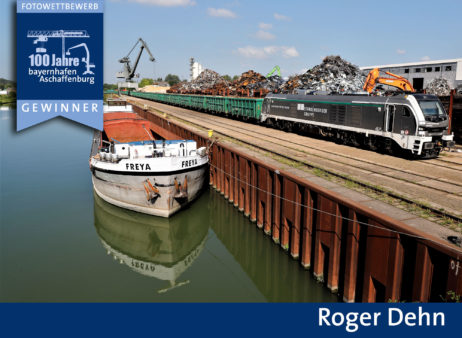

Aschaffenburg, 7 June 2021 – In its role as site architect, bayernhafen develops and operates commercial sites to enable raw materials, goods and products to reach their destinations. The efficient combination of inland waterway, rail and road means the ports actively contribute to the modal shift – and hence also to achieving environmental targets. In doing so, bayernhafen also takes the requirements laid down by the UN Convention on Biological Diversity and the Free State of Bavaria on the protection of biodiversity seriously, consistently implementing them in the planning and operation of its six sites in Aschaffenburg, Bamberg, Nuremberg, Roth, Regensburg and Passau.

Ongoing projects testify to the consistent manner in which bayernhafen Aschaffenburg promotes the protection of nature and greater biodiversity in the region:

Compensatory reforesting scheme on 2.8 hectares in the Hübner Forest

Longer and more frequent periods of drought and water scarcity demand a healthy forest stock of deciduous and coniferous trees. This demand has increased the importance of restructuring forests to achieve a stable mix of trees. bayernhafen is supporting the achievement of this goal through the planting of around 14,500 trees in the Hübnerwald (Hübner Forest) near Stockstadt, where a total of 2.8 hectares of mixed forest have been replanted in cooperation with the Hübner-Verwaltung Stockstadt under the expert guidance of the renowned environmental and landscape planning offices of Bosch & Partner GmbH.

“

Environmental protection and biodiversity go hand in hand – and we are fulfilling our responsibility.

Anja Bokeloh, Head of Technology and Operations at bayernhafen Aschaffenburg

Alexander Zeiger, Head of Real Estate Business at bayernhafen Aschaffenburg: “The mix of native tree species is preparing the forest to face the climate of the future.” The 14,500 seedlings planted are divided into 8,650 English oaks, 2,175 hornbeams, 2,175 sweet chestnuts and 225 each of winter lime, wild cherry, service tree, service tree, field maple, French maple and black walnut trees.

Anja Bokeloh, Head of Technology and Operations at bayernhafen Aschaffenburg: “We at bayernhafen Aschaffenburg are contributing towards reaching the environmental targets in a number of ways: through the very nature of our business, which involves shifting long-distance transport to the more environmentally friendly modes of inland waterway and rail, and additionally through nature conservation schemes such as tree planting, reforestation and the development of the habitat corridor at bayernhafen Aschaffenburg. Environmental protection and biodiversity go hand in hand – and we are fulfilling our responsibility.”

Protecting biodiversity through habitat corridor concept

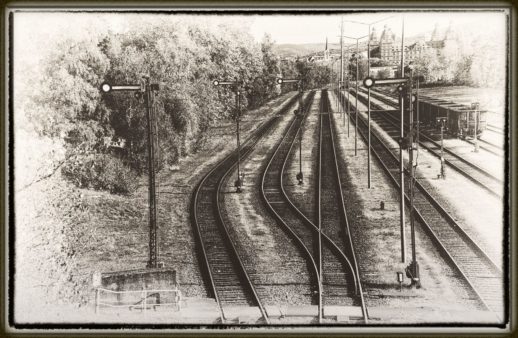

In the port itself, bayernhafen is doing its bit to protect nature and biodiversity. Currently, it is implementing a “habitat corridor concept” for bayernhafen Aschaffenburg. Connecting habitats ensures that animal species can survive – because when animals bridge the areas between the various habitats, they can establish contact and ensure their populations thrive.

Open land that is not used for commercial purposes is being developed to provide spawning grounds for amphibians and as habitats for reptilians, coupled with the creation of habitats for species such as natterjack toads and sand lizards. The core areas are connected inside the port through corridor structures running along the rail facilities and quay walls. To achieve this, bayernhafen Aschaffenburg is investing in specific structural measures, such as in the erection of protective fencing along roads and culverts for amphibians under paths; the preservation of hollow trees, creation of fallow structures, rock fills and deadwood piles as terrestrial habitats or winter habitats, and the establishment of spawning grounds. The experts from Bosch & Partner are also on board to provide environmental expertise and support.

Alexander Zeiger, Head of Real Estate Business at bayernhafen Aschaffenburg: “Alongside our core business – the development and management of industrial sites, commercial areas and transport facilities – we are also doing our bit for biodiversity, an extremely timely combination.”

“

Alongside our core business – the development and management of industrial sites, commercial areas and transport facilities – we are also doing our bit for biodiversity, an extremely timely combination.

Alexander Zeiger,

Head of Real Estate Business at bayernhafen Aschaffenburg

bayernhafen eco-account

The “habitat corridor concept” involves upgrading suitable areas to boost biodiversity, such as transforming fallow land into extensive grassland. The eco-account serves as an instrument for safeguarding and providing offsetting and compensation measures in advance that can be used to offset any adverse impacts on the natural environment in the future. Klaus Müller-Pfannenstiel, Managing Partner at Bosch & Partner: “Eco-accounts increase planning reliability and can speed up planning processes.”

“Port In Bloom” for schools and kindergartens in Aschaffenburg

In addition, in April, bayernhafen Aschaffenburg gifted 1,000 packets of seeds containing the “Port In Bloom” flower mixture to schools and kindergartens in Aschaffenburg. Each little packet contains enough seeds to create a bee-friendly flowering meadow 2.5 square metres in size. With the help of the children, more than 2,500 square metres of land will be turned into a flowering landscape that provides food for bees. As well as benefiting biodiversity, the flowers will also bring a wonderful splash of colour to the city in the summer months.

bayernhafen Aschaffenburg efficiently links the transport routes of inland waterway, rail and road, and is the key logistics hub for the Bavarian Rhine-Main region. It makes a significant contribution to the supply of goods to the region’s inhabitants and businesses and provides local companies with seamless access to international transport networks. As the largest industrial and commercial area in the Bavarian Lower Main region, its 157 ha of land provide space for ideal growth opportunities in a dynamic region to around 60 companies with approximately 2,800 employees.

bayernhafen comprises six corporate locations: Aschaffenburg, Bamberg, Nuremberg, Roth, Regensburg and Passau – major platforms for the global exchange of goods that efficiently link the transport modes of inland waterway, rail and road. In 2020, around 8.75 million tonnes of goods were moved by inland waterway and rail. bayernhafen acts as a ‘site architect’ that invests in high-performance infrastructure and cooperates closely with the companies settled in the ports to tap new potential for value creation between the different companies and across the different port locations.

800 hectares of total port area and more than 400 companies operating from its ports providing over 13,000 jobs make bayernhafen one of the best-performing logistics networks in Europe. The operator of the locations of Aschaffenburg, Bamberg, Regensburg and Passau is Bayernhafen GmbH & Co. KG. The Chief Executive Officer is Joachim Zimmermann. The Nuremberg and Roth locations are operated by Hafen Nürnberg-Roth GmbH, with an 80% share held by Bayernhafen GmbH & Co. KG, a 19% share held by the City of Nuremberg and a 1% share held by the City of Roth.

Hübnerverwaltung Stockstadt am Main

Hübner are a cooperative of forest owners, comprising two forester cooperatives, the upper forestry worker cooperative, Oberhübnerschaft, KdöR, and the lower forestry worker cooperative, Unterhübnerschaft KdöR, which consists of 142 foresters. The two cooperatives manage 951 hectares of forest, amounting to just over 50% of the total area of the Market Community of Stockstadt (approx. 1887 ha). (truncated extract from the Hübner website)

Bosch & Partner GmbH

Bosch & Partner GmbH delivers a wide range of services to provide goal oriented environmental and landscape planning and is a pioneer in environmental research. At its four locations in Herne, Munich, Hanover and Berlin, a team of landscape planners, landscape architects, biologists, engineers and geographers delivers planning, consulting and research services throughout Germany.